What is ASTM – Rubber Guidelines?

The ASTM rubber guidelines has over 12,000 standards. Within those standards, we’ll focus mostly on the D-2000.

What else does ASTM cover?

Many times, customers will ask engineers which specification should be used for a specific rubber compound.

SAE titles ASTM D2000 as the “Standard Classification System for Rubber Products in Automotive Applications.”

Why it’s necessary:

Automotive applications: This would be a start for a good ASTM rubber guidelines.

Industrial applications: There are no defined standards for medical applications yet.

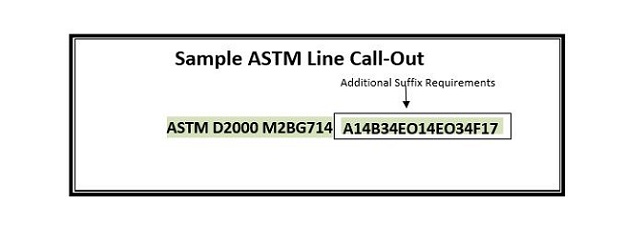

Below is a standard line call-out for a Nitrile rubber compound.

ASTM D2000: Document name.

M: The letter “M” may or may not be present – this represents the unit of measure, which is stated in SI (metric) units. If the “M” was not present, English units would be used.

2: Grade number. The grade number defines specific added test requirements, which are desirable in cases where the basic requirements may not ensure an acceptable material.

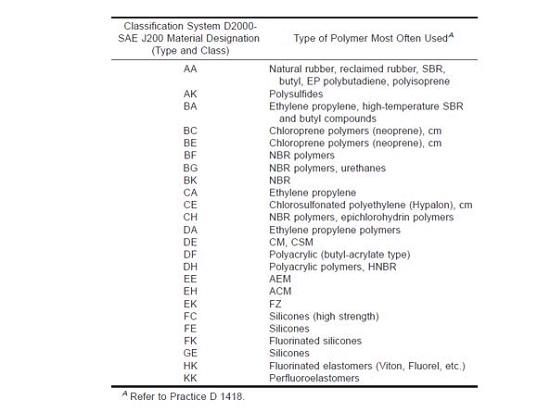

BG: Type and Class. The Type is based on changes in tensile strength.

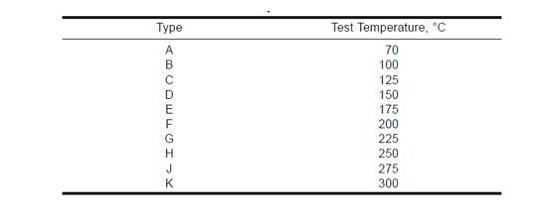

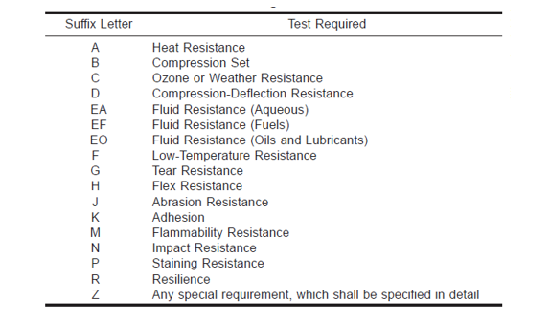

Type is based on change in tensile strength after heat aging for 70 hours at a given temperature, stated below: Pay attention to the test temperature.

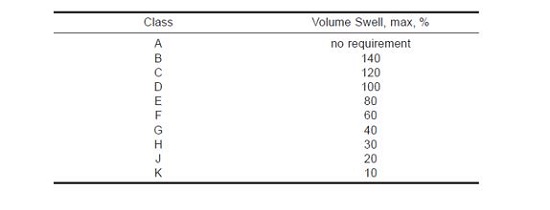

Class is based on the resistance of the material to ASTM Oil IRM903 after a 70-hour immersion. Below shows volume swell by class:

7: For standard physical properties, hardness is taken at ± 5.

Remember, this will be in SI units if the letter “M” is present in the call-out. To convert to psi, simply multiply the MPa number by 145. This is a value worth noting. Some have Z1 and Z2 if you need to add on.

Additional suffix requirements: A14B34EO14EO34F17

A14B34EO14EO34F17 is the second half of the original sample ASTM line call-out. This would be the suffix part of the ASTM.

If the rubber part will see high temperature exposure, it is wise to add a heat resistance requirement (A). This will add a tighter tolerance on physical property change after a heat age exposure.

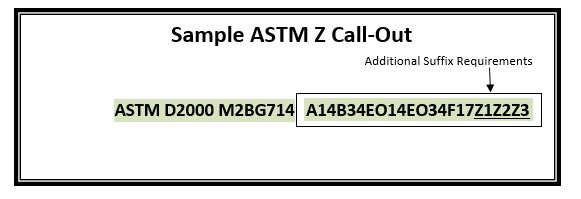

Special Requirements for ASTM D2000

Special requirements can be added using a “Z” call-out. Below are a few examples that we have seen over time:

Z1 – A14 Use Grade 4 requirements

Z2 – Color Blue

(Specific Color is required for a project)

Z3 – FDA 21 CFR 177.2600 complaint

ASTM Tips to remember:

1) Using basic call-outs can give more robust compounds.

Calling out the compound helps build and test and repeat. Finding a good compound is important. Do not over engineer the compound. Keep it as simple as possible. Sometimes the geometry could help. You want to find the best mix of using the base material and modifying the formula. Sometimes picking the wrong base material makes it hard to change the formulation. Selecting the correct formulation and base material is important. To meet an engineered specification, this is typically the first place to start. Sometimes, the material can be make thicker or thinner to achieve the same performance requirement. UV rays? Oxidations? Sometimes material reductions can take place. Other times, weight reductions can take place.

Sometimes a cycle testing is needed.

This can be performing over 1 million cycles. This take time and often time money. ARDL helps with the material side. You must do this in a lab setting. Do to this in China. CNAL is a good choice. You will want to test this in the environment.

The best way is to use the real live test. Duplicate the humidity. Don’t do this too fast. This can cause problems as well. Keep it short and simple. Don’t cut corners. Do not take the easy way out. You want to emulate the real environment. This is the zone in which pricing and cost plays a role.

Have a question? Please fill out the form below to receive information regarding your inquiry. You may also give us a call at (626) 965-9966.

Error: Contact form not found.