ASTM D412 – Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers

ASTM D412 is a test method for evaluating the physical properties of vulcanized rubber and thermoplastic elastomers(TPE). Developed by ASTM International, it provides a standardized procedure to determine the tensile strength, elongation, and other critical properties of elastomers used in a variety of industries, including automotive, medical, and manufacturing.

This test is vital for ensuring that rubber materials meet the performance requirements for their intended applications. Whether it’s for gaskets, seals, or medical devices, understanding the results from ASTM D412 can help ensure that the materials will perform reliably under stress, temperature changes, and other mechanical forces.

What Does ASTM D412 Test?

ASTM D412 evaluates the following key properties of elastomers:

- Tensile Strength: The maximum amount of stress that the rubber material can withstand without breaking. This is a key indicator of the rubber’s durability and resistance to wear.

- Elongation at Break: This measures how much the rubber can stretch before breaking, which helps determine its flexibility and resilience. A high elongation value indicates that the rubber can stretch significantly before failure.

- Modulus at Specific Strains: The stiffness of the material at specific elongation percentages (such as 100% or 300%) can give insight into its elasticity.

- Tear Strength: Some variations of the ASTM D412 test also measure how resistant the rubber is to tearing, which is important in evaluating materials for high-stress applications.

- Other Properties: Depending on the specific variation of ASTM D412, additional tests like the effect of aging, temperature, or chemical exposure may be assessed.

How Does ASTM D412 Work?

The ASTM D412 test is performed using a universal testing machine (UTM), which is designed to stretch a rubber sample and measure its response to applied forces. The test typically follows these steps:

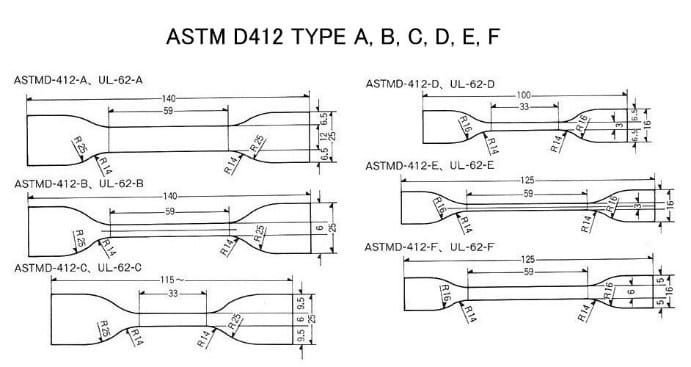

- Sample Preparation: The rubber sample is cut into a specific shape, often in the form of a dumbbell, to ensure uniformity during the test.

- Testing Conditions: The sample is placed in the testing machine, which applies a constant tensile force. The sample is stretched at a consistent rate until it reaches its breaking point.

- Data Collection: The UTM(Universal Testing Machines) records the amount of force applied and the elongation (stretching) of the sample. The data is used to calculate the tensile strength, elongation at break, modulus, and other relevant material properties.

- Analysis: The data helps manufacturers assess the suitability of a material for specific applications.

Why ASTM D412 is Important

- Quality Control: ASTM D412 provides manufacturers with reliable data to ensure that rubber and elastomer products meet specific strength, flexibility, and durability requirements. This is crucial for product consistency and quality assurance.

- Material Selection: The results of the ASTM D412 test can guide the selection of the most appropriate elastomer for a particular application. For example, some applications may require rubber with higher elongation for flexibility, while others may prioritize tensile strength for load-bearing capacity.

- Product Development: In the development of new rubber products, ASTM D412 helps engineers understand how material formulations affect the final product. It enables the modification of rubber compositions to meet desired performance standards.

- Compliance and Certification: Many industries require ASTM-certified testing to ensure that products meet regulatory and safety standards.

Applications of ASTM D412

Various industries use ASTM D412 testing including:

- Automotive: For seals, gaskets, and hoses that must withstand high stress and extreme conditions.

- Medical: For rubber materials used in medical devices, such as seals, tubing, and gaskets, where performance reliability is crucial.

- Consumer Goods: For products like footwear, rubber bands, and sporting equipment.

- Industrial: For materials used in machinery, conveyor belts, seals, and O-rings, where both tensile strength and flexibility are essential.

- Aerospace: For rubber components used in seals, gaskets, and other critical applications that require extreme durability and reliability.

Benefits of ASTM D412 Testing

- Accurate Material Assessment: Provides clear, quantifiable data about the mechanical properties of rubber and elastomers.

- Customization: Helps in developing custom formulations to meet specific requirements for strength, flexibility, and other material properties.

- Industry Standard Compliance: Ensures your products meet ASTM standards, which is often a requirement for regulatory approvals and industry certifications.

Types of ASTM D412 Test Methods

ASTM D412 includes several methods adapted depending on the application. These include:

- Test Method A: Tensile testing of vulcanized rubber using a type A specimen.

- Test Method B: Testing of rubber materials using a type B specimen (often used for thin materials or films).

- Test Method C: Variation of tensile testing used for testing thermoplastic elastomers.

- Test Method D: Specialized testing for the effects of heat, aging, or other environmental factors on rubber materials.

Conclusion

ASTM D412 testing is a crucial step in ensuring the quality, performance, and reliability of rubber and TPE used in a wide variety of industries. Manufacturers can ensure their products meet both customer and regulatory requirements, reducing the risk of failure and improving product longevity.

If you require ASTM D412 testing for your rubber or elastomer products, we offer reliable, accurate testing services to help you make informed decisions about your materials and products. Contact us via email sales@coirubber.com or call us at (626)-965-9966 today to learn more!