ASTM D945 – Standard Test Methods for Rubber Properties in Compression or Shear

ASTM D945 is a standard test method developed by ASTM International for determining the properties of rubber in compression or shear using a mechanical oscillograph. This method provides important data about the behavior of rubber materials under conditions of deformation, which is essential for industries that rely on rubber components, such as automotive, aerospace, and manufacturing. By testing rubber’s mechanical properties under controlled conditions, ASTM D945 helps ensure that materials used in various applications meet performance specifications and durability requirements.

What is ASTM D945?

ASTM D945 is a standard test method used to measure the mechanical properties of rubber, specifically focusing on compression and shear behaviors. This test is conducted using a mechanical oscillograph, which subjects rubber samples to oscillatory forces and records how the material responds to cyclic deformation. The results of the test help determine important material properties such as resilience, stiffness, and damping, which are crucial in applications like seals, tires, gaskets, and other rubber components that must withstand mechanical stress and strain over time.

The Importance of Testing Rubber Properties

Understanding the mechanical properties of rubber is vital for evaluating its suitability for different applications. Rubber components are often exposed to dynamic forces, such as compression, shear, and oscillatory motion. Testing rubber’s behavior under such conditions helps to:

- Predict Performance: By assessing how rubber behaves under mechanical forces, manufacturers can predict how it will perform in real-world applications.

- Ensure Durability: Rubber components must be durable enough to withstand repeated compression, stretching, and shear forces without degradation.

- Improve Design: The data from the test allows engineers to optimize rubber formulations and designs for improved performance in end-use applications.

- Quality Control: Regular testing ensures that rubber products meet the required specifications for mechanical properties, maintaining consistency and reliability.

Test Procedure: How ASTM D945 Works

The ASTM D945 test method involves using a mechanical oscillograph to subject rubber samples to oscillatory shear or compression forces. The procedure typically follows these steps:

- Sample Preparation:

- Test Setup:

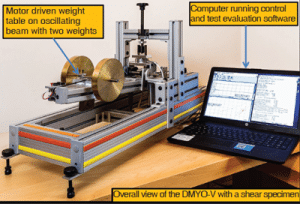

- The rubber sample is placed in a mechanical oscillograph apparatus, which is designed to apply cyclic forces to the sample. The oscillograph applies alternating compression or shear forces to the sample over a defined frequency range.

- Oscillatory Testing:

- The rubber sample is subjected to oscillatory shear or compression deformation. The mechanical oscillograph measures the response of the rubber to the applied forces, typically recording parameters like force, displacement, and phase shift during the test.

- Data Collection:

- The machine measures the rubber’s resistance to deformation, the damping characteristics, and its resilience during oscillations. These results provide insight into the material’s mechanical properties, including:

- Storage Modulus: Indicates the rubber’s stiffness and energy storage capability.

- Loss Modulus: Measures the rubber’s energy dissipation during deformation (damping).

- Damping Factor: Reflects the amount of energy lost in each cycle of deformation.

- The machine measures the rubber’s resistance to deformation, the damping characteristics, and its resilience during oscillations. These results provide insight into the material’s mechanical properties, including:

- Post-Test Analysis:

- The data collected during the test is analyzed to determine the rubber’s mechanical properties. Key parameters such as the rubber’s resilience, damping characteristics, and viscoelastic behavior are evaluated. The results help manufacturers understand how the rubber will perform under dynamic loading conditions.

Key Benefits of ASTM D945 Testing

- Material Characterization: ASTM D945 provides detailed insights into the viscoelastic properties of rubber, which are essential for developing high-performance materials.

- Quality Control: Regular testing ensures that rubber components meet performance standards and are consistent in quality.

- Predictive Performance: The test helps predict the material’s behavior in real-world applications, aiding in the design and selection of the right rubber for specific applications.

- Optimization: Manufacturers can fine-tune their rubber formulations for improved performance based on the test results.

Outcomes and Typical Results of ASTM D945

The typical outcomes of an ASTM D945 test include:

- Resilience: The ability of the rubber to return to its original shape after being deformed, indicating how well it can withstand repetitive loads.

- Viscoelastic Behavior: Data on how the rubber behaves under both elastic and viscous conditions, which is essential for predicting performance under dynamic forces.

- Storage and Loss Modulus: These measurements give insight into the rubber’s stiffness (storage modulus) and its ability to dissipate energy (loss modulus), which are crucial for designing components that endure repeated mechanical stress.

For example, a rubber compound with a high storage modulus will be stiffer and more resistant to deformation, making it ideal for applications requiring high strength. On the other hand, a compound with a higher loss modulus may be better suited for damping applications, such as vibration isolation.

Who Uses ASTM D945?

ASTM D945 is used by various industries that rely on rubber components and materials:

- Rubber Manufacturers: To characterize and improve the mechanical properties of rubber compounds.

- Automotive Industry: For testing rubber parts like tires, seals, bushings, and gaskets that must withstand dynamic forces.

- Aerospace Industry: For rubber components used in high-stress applications, such as seals and vibration dampers.

- Research and Development: To develop new rubber formulations with optimized mechanical properties for specific applications.

- Testing Laboratories: To provide quality assurance and certification for rubber products, ensuring they meet performance specifications.