Material Technology

Material Technology

COI Chemist Engineer Specific material compounds for individual needs. We understand that our customers need to know the parts we supply will perform as required in service, each and every time. That’s why we pay close attention to application variables and help our customers choose the best rubber and plastic materials — based on physical, chemical and thermal requirements — for each situation. We can also formulate and test custom compounds in our material development laboratories or any other A2LA certified laboratories.

| RUBBER TECHNOLOGY IS CONDUCTED WITH A TRANSFORMATION OF ELEASTOMERS INTO USEFUL PRODUCTS | |

|

|

| MATERIALS COMMONLY USED WITH CUSTOMER COMPOUND MIXES | |

| AA – NR, RR, SBR, EPDM, polybutadiene, polyisoprene | DE – CM, CSM |

| AK – Polysulfides | DF – Polyacrylic (butyl-acrylate type) |

| BA – EPDM, high temp SBR, Butyl compounds | DH – Polyacrylic polymers, HNBR |

| BC – Chloroprene Polymers (neoprene®) | EE – AEM |

| BE – Chloroprene Polymers (neoprene®) | EH – ACM |

| BF – NBR Polymers | EK – FZ |

| BG – NBR Polymers – Urathanes | FC – Silicones (high strength) |

| BK – NBR | FE – Silicones |

| CA – Ethylene propylene (EPDM) | FK – Fluorinated silicones |

| CE – Chlorosulfonated polyethylene (Hypalon), cm | GE – Silicones |

| CH – NBR polymers, epichlorohydrin polymers | HK – Fluorinated elastomers (Viton®, Fluorel®, etc.) |

| DA – Ethylene propylene polymers | KK – Perfluoroelastomers |

| PROUDLY USING GE, SHIN-ETSU, BAYER, DOW CORNING, JSR, DSM, SMR, TTR, AND OTHER WELL RESPECTED SUPPLIERS FOR CUSTOMER COMPOUNDS BUILDS | |

Material Technology

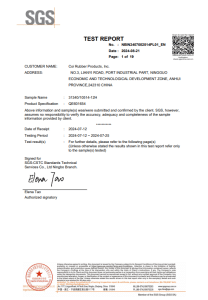

In the ever-evolving landscape of material science, our research team recently conducted an in-depth study on silicone rubber, specifically focusing on formulations compliant with AMS 3303L standards. This particular standard, known for its stringent requirements, includes a tear strength evaluation at 100 ppi, a crucial property for ensuring durability and performance in demanding applications. To validate our formulations, we employed the ASTM D2137 Method C, a rigorous test designed to assess low-temperature flexibility and brittleness—a key factor in the longevity and reliability of silicone products. Our laboratory testing, detailed in the accompanying PDF report, demonstrates how our compound not only met but exceeded the required thresholds, showcasing our ability to engineer materials that perform under extreme conditions.

Material Technology

The challenge of achieving compliance with both AMS 3303L and ASTM D2137 Method C cannot be overstated. These tests demand precision in formulation and an understanding of the intricate behavior of silicone under stress. Our success is a testament to our scientific approach, leveraging advanced chemistry and state-of-the-art equipment to fine-tune every aspect of the compound.

This achievement underscores our capability in formulating special compounds tailored to specific needs, ensuring that our products meet the highest standards of quality and performance. The PDF test results provide a clear demonstration of our expertise and dedication to innovation in the field of silicone rubber development.

Have a question? Please fill out the form below to receive information regarding your inquiry. You may also give us a call at (626) 965-9966.