Injection Molding

About Injection Molding

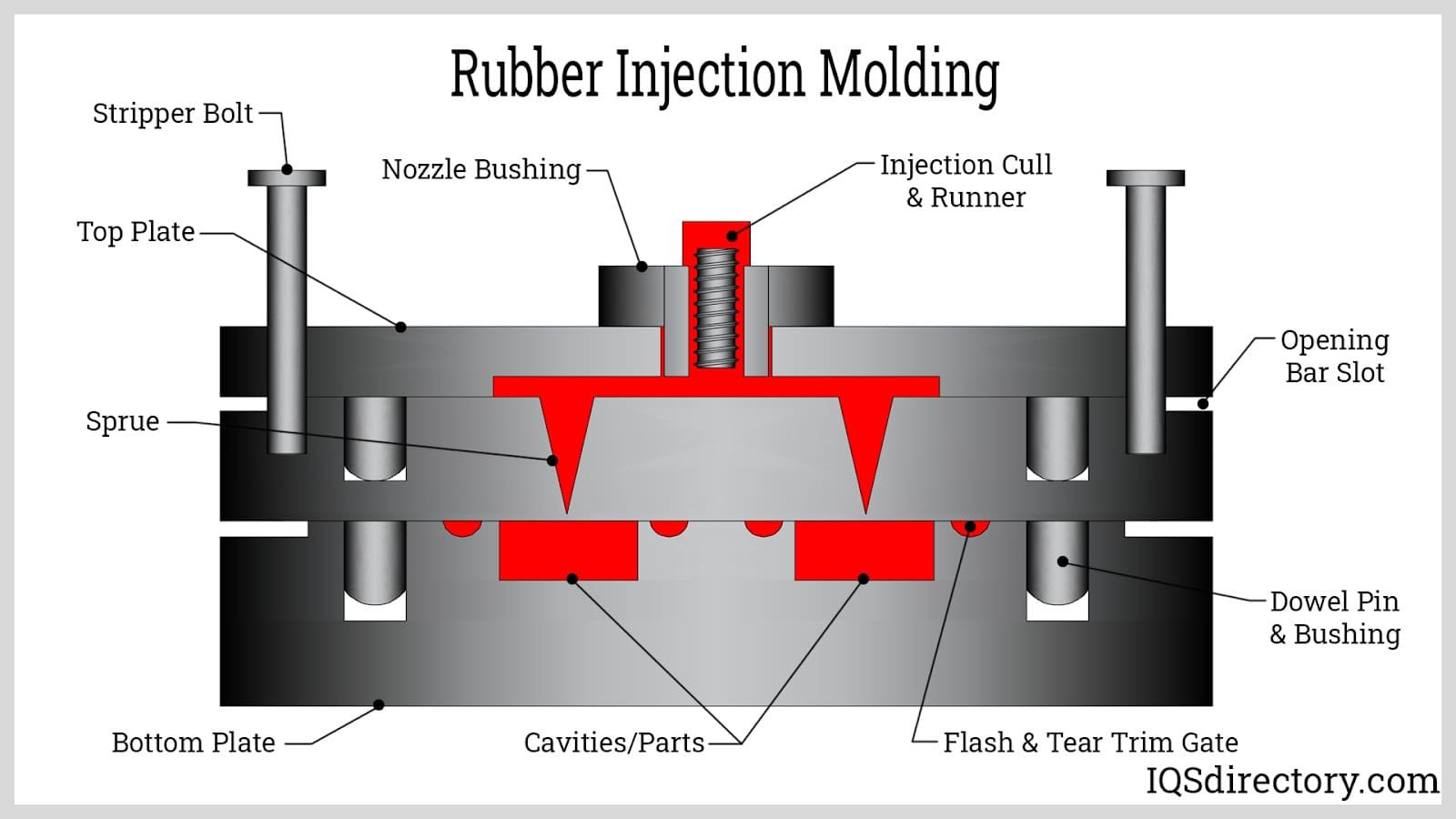

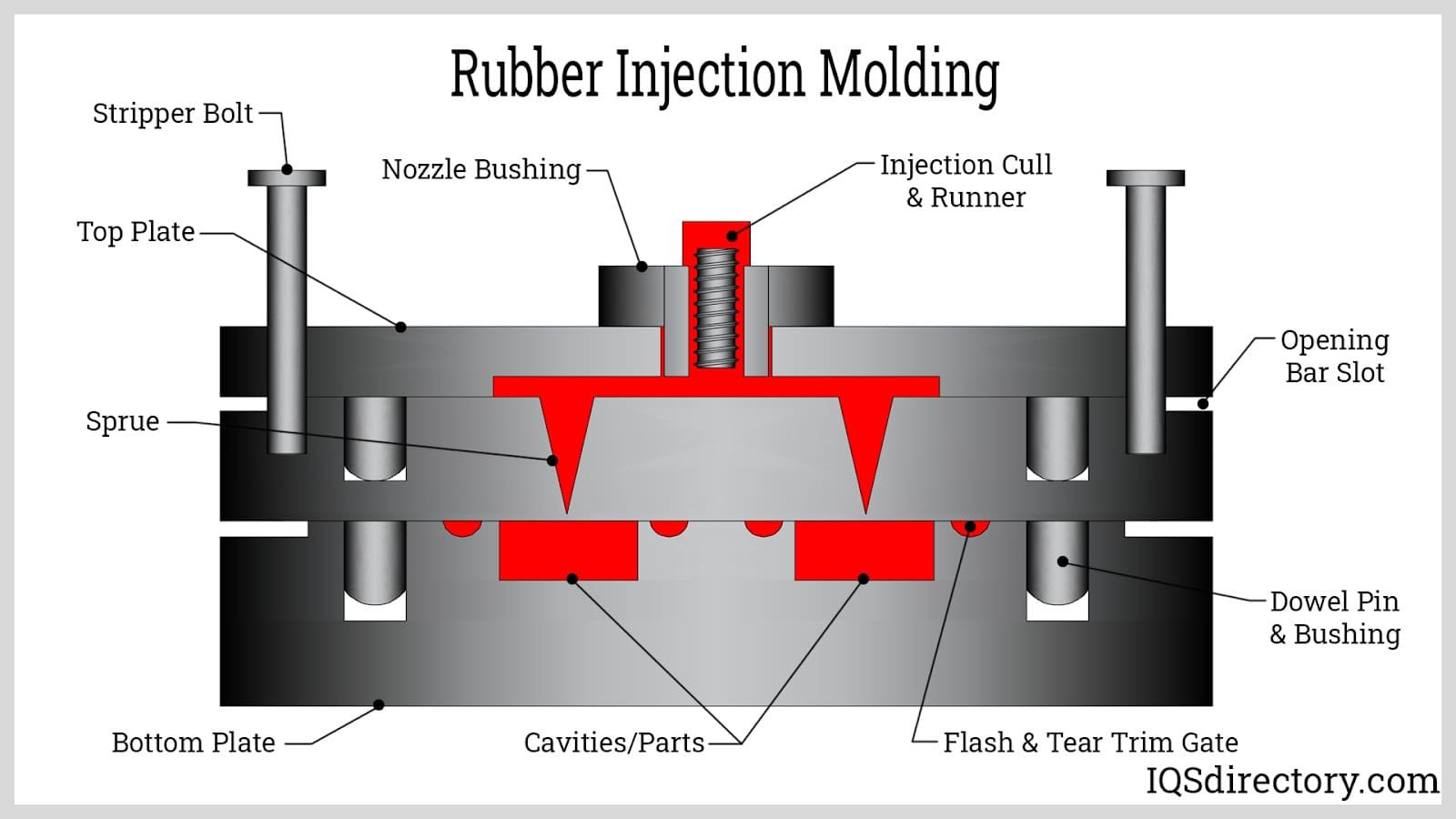

Injection molding rubber is a combination of injection and transfer molding that Coi Rubber Products uses quite frequently to maximize the number of cavities in a given footprint. It is commonly used within liquid injection and/or LSR molding. Some classifications with liquid injection versus transfer injection would further provide subcategory classifications.

Injection Molding

- Perfect for large volume runs of small-to-medium size parts

- Good for intricate metal inserts, thin-wall diaphragms and similar components requiring uniform physical properties

- 300 ton to 1000 ton clamping pressure

Advantages of Injection (LSR) Molding Rubber:

- Tooling can be more complex and higher precision than compression

- Material properties created within A/B mix can have superior properties

- Process is suitable from most elastomers and cure systems

- Cycle times may be shorter reducing time while increasing efficiency

- Complete elimination of pre-forms, a labor-intensive step that can introduce variability in pre-form weight and shape resulting in variability of the finished product.

Disadvantages of Injection Molding vs. other rubber molding methods

- Labor for preforming material can add cost (however offshore manufacturing curtails this problem)

- Cycle times may be longer (additional shifts counter this problem)

- Tooling can be more complex and higher cost to construct than compression

- Higher percentage material runner scrape vs. compression molding

Have a question? Please fill out the form below to receive information regarding your inquiry. You may also give us a call at (626) 965-9966.